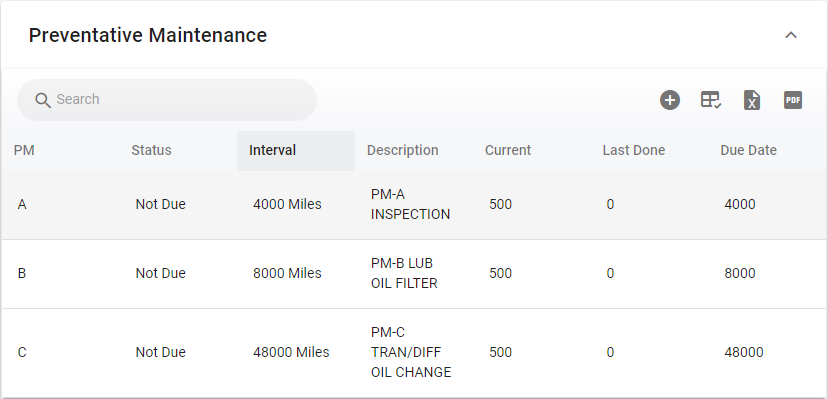

Asset PM Tab (Preventative Maintenance)

Preventative Maintenance Panel

One of the many cost-saving features in the RTA Software is the ability to track and schedule asset Preventive maintenance schedules.

The PM panel can be used to add PM schedules, view set PM schedules, and export the PM schedules.

This article will give an overview of the info contained in the panel. For assistance with creating a PM for an asset, refer to Preventive Maintenance Schedules.

To locate the PM information for an asset, start on the main menu and navigate through Assets → Choose and click on the Asset to view → PM

Icons on PM Panel

Allows user to add a PM – Refer to PM Schedules in Fleet360 for detailed instructions on adding a PM to an asset

Allows user to adjust the columns viewed – Refer to Customizing List columns in Fleet360 for information on how to adjust columns

Allows user to export the PM Schedule via Excel and PDF – refer to Exporting Lists in Fleet360 for information on exporting

Viewing PM schedules in RTA Software

Once PMs are set up for the asset, the PM Schedule overview information will always display in the Preventative Maintenance Overview panel located by clicking PM from the asset file menu.

PM Schedule Overview Field/Column Descriptions

PM – Refers to the PM Code which is used to identify the PM

Status – Denotes the status of the PM based on intervals set such as not due, due soon, or overdue

Interval – Displays the primary interval for this PM such as every xx miles or xx days

Description – Gives a description of the PM Code

Current – Displays the current meter reading for the asset

Last Done – Will display either the last interval type reading such as the meter reading (if intervals are by mileage) or the last date (if intervals are by days) that the PM was completed

Due Date – Displays the next meter reading when the PM will be due based on interval type such as mileage or the next date when the PM will be due if intervals are by miles or days

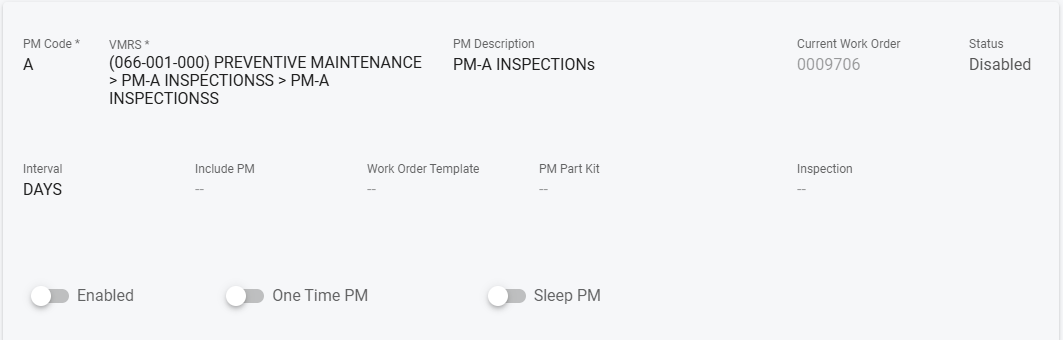

Click on a PM line item to open up the details on the PM including information, intervals and history. A pop out panel will open and 3 panel sections will be displayed.

PM Info

Below is a listing of the tabs and fields that display which are editable after the PM is created.

Refer to PM Schedules in Fleet360 for a complete list of descriptions for each field.

Editing a field requires the user to click in the field, change/add the appropriate data, and click the check mark to save the change.

PM Info Panel

PM Code - The assigned PM code for the service or inspection. Can be a letter by itself or a letter and a number combination

VMRS - The VMRS job code assigned to the PM which will trigger a completion from the work orders

PM Description - The job description for the work being done on the PM (this comes from the VMRS file and is associated with the VMRS code used in this section)

Current Work Order – Will display an open work order for the asset that contains this PM as a job line if applicable.

Status – Restates the PM status for the asset based on the input interval for the PM

Examples may include the following:

Blank = Not Due

Due Soon = PMs that are within 14 days of their “due today” threshold

Due Today

Past Due

Interval - The trigger interval for the PM to show it is due. these intervals can include days/months, miles/hours, fuel gallons, and up to 4 alternate meters

Include PM - Shows any linked PMs, also known as nested PMs

Work Order Template - to edit this field, WO templates need to have already been established via Fleet360.

Refer to Work Orders Templates for instructions on adding a Work Order Template in RTA Fleet360.

PM Part Kit - To edit this field, Part Kits need to have been established. Refer to Part Kit for instructions on creating and posting part kits

Inspection – A paperless inspection may be attached to the PM if the templates have been built and exist in RTA

Refer to Creating an Inspection Template and Assigning and completing paperless inspections for more information

Enable Toggle – Allows the user to disable and re-enable the PM schedule (The PM will stay disabled until manually re-enabled using the toggle)

One Time PM option – Changes the PM to only be in effect once (For example, a PM set up to do a thorough inspection on an asset prior to its warranty expiring)

Sleep PM option – Pauses the PM schedule based on a date range (For example, school buses that are not in use over a summer break)

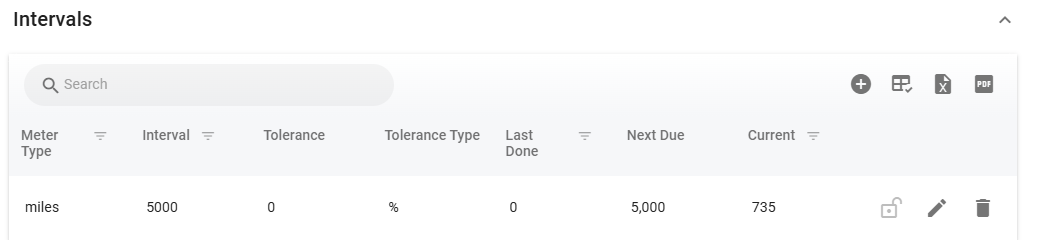

Intervals Panel

Below is a listing of the fields that display in the Intervals panel.

Refer to PM Schedules in Fleet360 for a complete list of descriptions for each field.

Editing a field requires the user to click in the field, change/add the appropriate data, and click the check mark to save the change.

Action Icons - Icons at the top of the panel allow users to take specific actions

= Add a new interval to the PM

= adjust column view

= export panel into excel or PDF

Meter Type - What primary meter is being tracked (Miles, Hours Gallons etc.)

Interval - This represents the trigger interval which can be in Days, Months, Miles, Hours, Gallons or up to 4 Alt Meter categories

Tolerance - This allows you to set a +/- tolerance level for a PM as either a percent of the interval or a set number against the interval. This sets the acceptable done early or done late parameter for PM compliance. (Range at which the PM is still considered to be done on time)

Tolerance Type - If a tolerance threshold is set for the interval, this will display whether that tolerance is set as a percentage or number of days against the interval.

Last done – Displays the meter/interval reading when the last PM was completed

Next due – Displays the meter/interval reading or date for the next PM based on interval

Current – Reiterates either the current meter reading or current date

Lock Icon - Locking the interval means the next due will consistently trigger off of Due and not when done

Note: The Interval Lock option allows one to modify how the next due point gets calculated. With a PM Unlocked the system calculates the last done which normally comes from the completed line on a work order (Last Done + PM Interval = Next Due). With a PM Locked the “Next Due” is set by the end user and the system calculates forward from that number (Next Due + PM Interval = New Next Due). This is particularly handy for things like DOT and/or State Inspections.

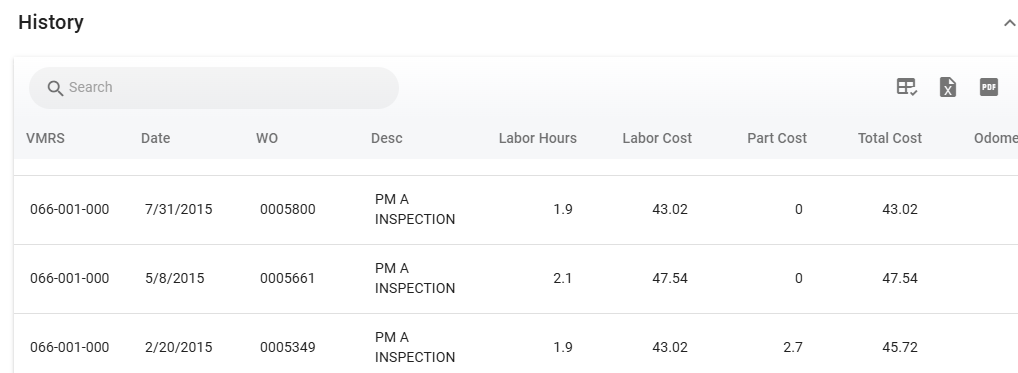

History Panel

The history panel will display a report or list of the PMs performed on the asset over time. Users can customize columns and export the data to Excel and PDF.

Refer to Customizing List Columns for instructions on customizing columns and Exporting Lists for exporting files from Fleet360.