Mechanic Accountability

Summary/Use Case

Report Summary

The Mechanic Accountability report provides a comprehensive record of mechanic activity, including job statuses, time spent, vehicle involvement, and job details. This report is essential for fleet managers to monitor and analyze mechanic productivity and job allocation efficiency.

Use Case

Track and document individual mechanic activities and job statuses.

Monitor time allocation on specific job tasks to manage labor costs.

Review completed job details to ensure accurate job performance records.

Identify patterns in job types and frequencies to support planning and training.

Support auditing processes by providing an accountability log for mechanic tasks.

Location: Where to Find It

Reports > RTA Standard Reports > Employee > Mechanic Accountability

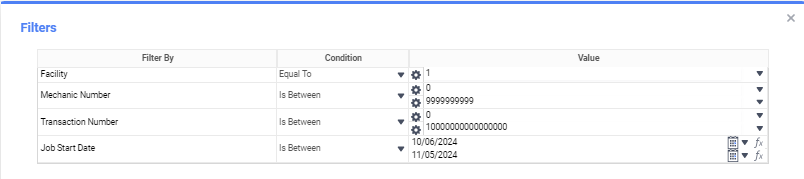

Data Filter Prompts

You will be prompted for filtering of the data to specify and narrow down the data that will be pulled. See the Data Filter List below for options.

Data Filter List

Filter Name | Recommended Filter Condition(s) | Value (Options) | Value (Default) | Value (Notes) |

|---|---|---|---|---|

Facility | Equal To | Facility ID (e.g., 1) | 1 | Specify a particular facility. |

Mechanic Number | Is Between | 0 to 999999999 | 0 to 999999999 | Full range of mechanic numbers. |

Transaction Number | Is Between | 0 to 1000000000000000 | 0 to 1000000000000000 | Full range of transaction IDs. |

Job Start Date | Is Between | Custom date range | 10/06/2024 to 11/05/2024 | Select start and end dates to define report scope; default date range goes from today to one month ago |

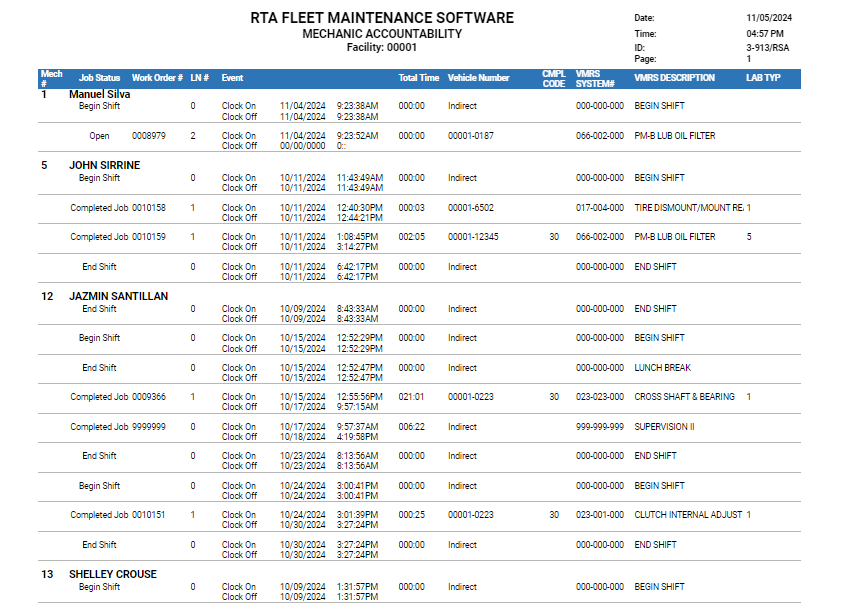

Report Output and Data Elements

Report Output

Once the "Mechanic Accountability" report is run, users will see a detailed log of mechanic activities, sorted by mechanic number, job status, event, and associated time entries. The report lists job start and end times, work order numbers, vehicle numbers, and task descriptions, allowing for detailed analysis of mechanic engagement. This breakdown allows fleet managers to observe the distribution of mechanic activities, time allocation, and job details, assisting in resource management and performance evaluation.

Report Data Elements

Column Number | Column Title | Data Notes |

|---|---|---|

1 | Mech # | Mechanic identifier number. |

2 | Job Status | Current status of the job (e.g., Begin Shift, Completed Job). |

3 | Work Order # | Unique identifier for the work order. |

4 | LN # | Line number within the work order. |

5 | Event | Event type such as "Clock On" or "Clock Off". |

6 | Date | Date of the event. |

7a | Start Time | Starting time of the job or event. |

7b | End Time | Ending time of the job or event. |

8 | Total Time | Total time spent on the task. |

9 | Vehicle Number | Identifier for the vehicle involved in the job. |

10 | CMPL Code | Compliance code related to the job. |

11 | VMRS System | Vehicle Maintenance Reporting Standards system code. |

12 | VMRS Description | Description of the task performed as per VMRS. |

13 | LAB TYP | Labor type for the task. |